|

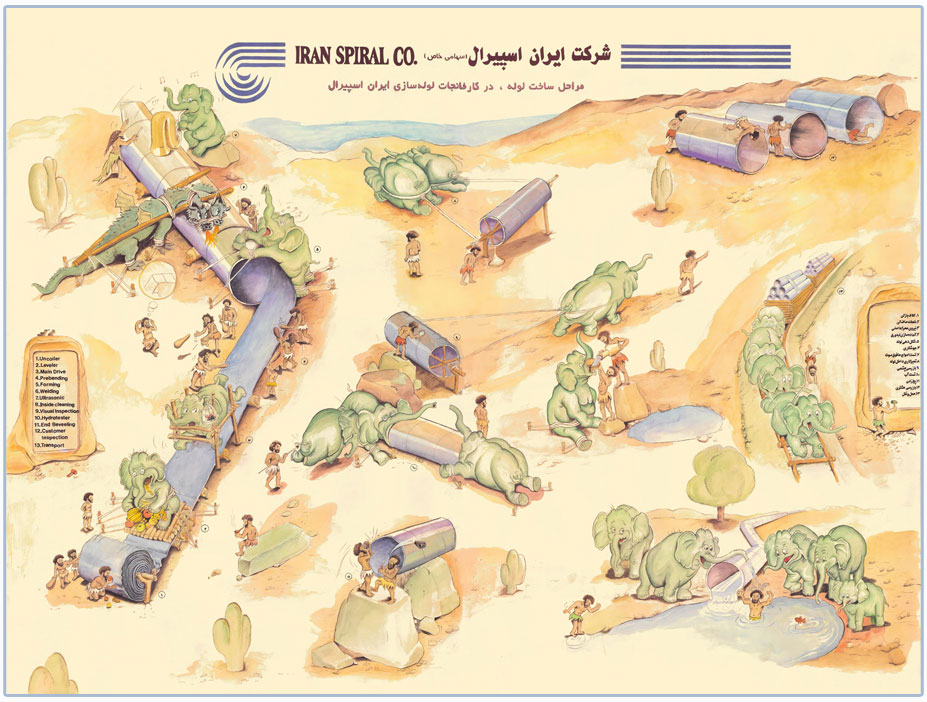

ISCO's Production Lines

were designed by Hoesch, Germany and PRD,USA, respectively

employing two different technologies, namely external cage forming versus free

forming.

The welding

method is Submerged Arc welding (SAW), which is an automatic process with very

high quality output. These pipe mills can also produce steel quality up to grade

X70 according to API5L standards.

To ensure

the weld quality, pipes will be ultrasonic tested continuously by an in-line

ultrasonic testing facility applying back pulse echo method. After Cutting the

pipe to the desired length it will be pressure tested with test pressure being

1.5 times the target pressure to ensure proper pressure resistance. After Hydro

test, both pipe ends are beveled and after final inspection and in-line

weighing, pipes will be transported to the pipe storage area.

Production Line

Copyright ©

2010 - 2011 Iran Spiral Co.

|